Contact Information

Mobile:+8615937149572

Mobile:+8618339801888

Mailbox:zzylxs@126.com

Office address: Floor 5, Block B, Building 3, Hatching of Henan National University Science Park, No.11 Changchun Road, High-tech Industrial Development Zone, Zhengzhou City, Henan Province

Production headquarters: China. No. 5288-7, East Side of Heshuo Avenue, Industrial Agglomeration Area, Wuzhi County, Jiaozuo City, Henan Province

3 Compartment Cornstarch Based Meal Box

It is suitable for manufacturing plastic packaging boxes, trays, cushions, linings, auto parts and medical equipment, etc. Injection molding is widely used in the manufacture of electronic device shells, auto parts, plastic toys and home appliances.

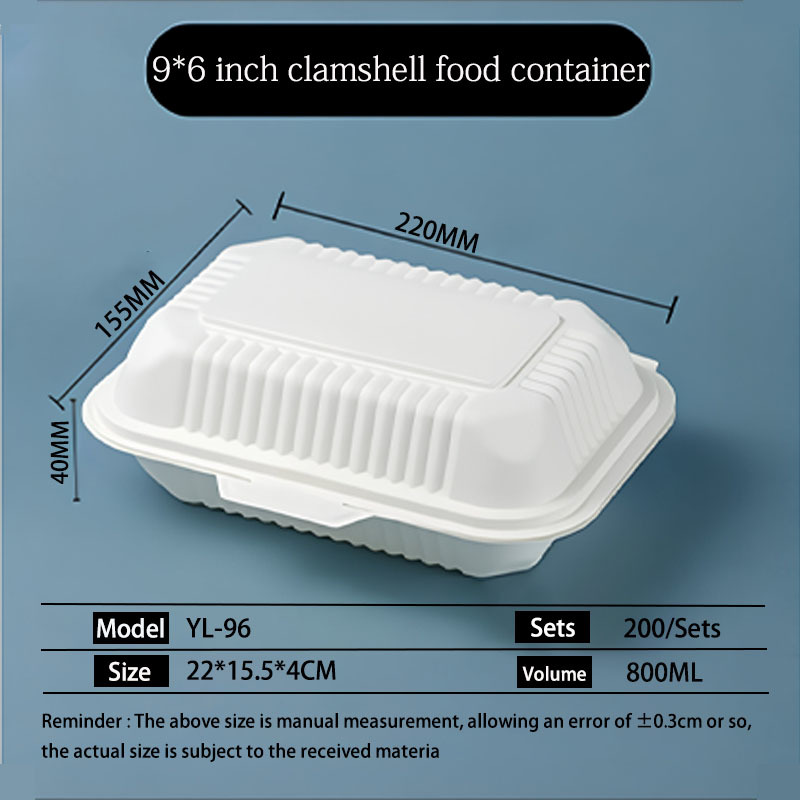

- Commodity name: 3 Compartment Cornstarch Based Meal Box

Product Details

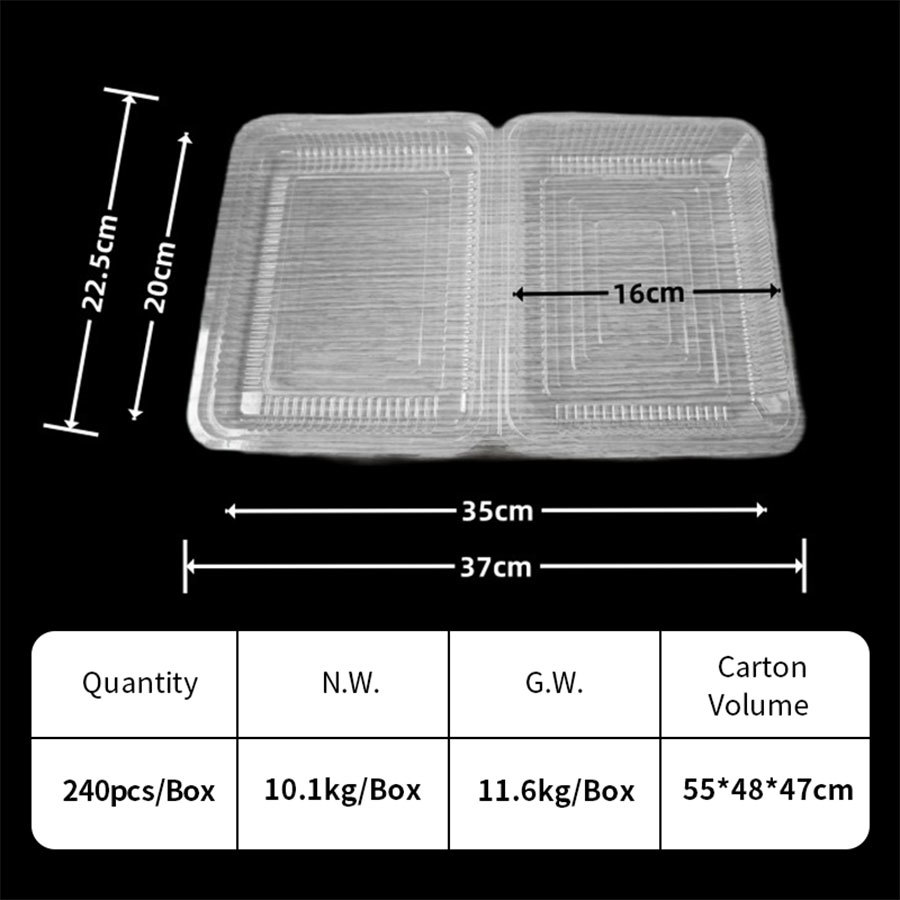

Blister and injection molding are two different plastic processing technologies, and they have obvious differences in process principles, material use, and application fields.

The following is the specific difference between blister and injection molding:

The process principle is different. Blister is by heating the softening of the plastic sheet or plate adsorption to the mold surface, and then cooling molding process; injection molding is the heating and melting of plastic particles into the closed mold, cooling and curing molding.

The materials used are different. Blister mainly uses PVC, PET, PS and other thermoplastics; injection molding is more thermosetting plastics, such as PA, PC, ABS and so on.

The scope of application is different. Blister is suitable for the manufacture of plastic packaging boxes, trays, cushions, linings, auto parts and medical equipment, etc.; injection molding is widely used in the manufacture of electronic device shells, auto parts, plastic toys and home appliances.

Accuracy and repeatability are different. The precision and repeatability of blister is usually lower than that of injection molding.

Production costs and efficiency are different. Blister usually requires less initial cost and is more suitable for small batch production; injection molding has higher cost but higher production efficiency and is suitable for mass production.

The product features are different. Blister products usually have good flexibility and impact resistance, but low strength and durability; injection products have high precision, high strength and excellent dimensional stability.

Our Starch-Based tableware are available in a variety of shapes, sizes, and compartments. Starch-Based tableware with lids are available. Contact our sales team for samples and more information.

Starch-Based Tableware for Food Service

They are suitable for a wide range of cuisines, food styles and applications. The trays can be pre-prepared days earlier and in a larger quantities, sealed for freshness and stored fresh or frozen, then simply heated or cooked.

Key words:

Previous: 4 compartment meal box (4G01)

Related Products